Soldering

|

The soldering is the basic work for electronic circuit engineering. I will introduce the tools for soldering below.

The sufficient attention is necessary during work, because soldering handles a high temperature. Pay attention to the handling of the soldering iron sufficiently, because it becomes burn, fire more, carelessly.

Solder is hardening in a normal temperature, but solder can melt easily by using the soldering iron and the parts and wiring materials can be fixed to the printed wiring board(PWB). The important piont is temperature of the soldering iron. For soldering, it needs to become the temperature of the object(PWB, parts, wire etc) to solder melting temperature. However, the temperature of soldering iron must not be too high. The electronic component gets damage with high temperature. So, you need to solder in a short time. Sometimes, the loose contact of soldering occurs. It is difficult to confirm only by looking at. When the temperature of the object is not enough, the loose contact will be occured. At the end of assembling of the electronic circuit, you need to check the soldered contact with circuit tester etc. Electric power (Calorific value is decided with this)

25W type

In case of thick copper plate, the heat is easy to escape and the temperature rise is difficult.

|

|

There is the type that the tip of soldering iron is made of copper stick. But I don't recommend that type. Because, the copper stick rusts easily by heat and it becomes difficult to convey heat. Also the tip of copper stick melts with solder. It becomes difficult to sloder. I recommend the one that is using a special metal for tip. It is difficult to rust and melt. The tip of iron must keep clean. When it get dirty, it becomes difficult to convey heat. There are many shape of tips. The tip which fit to the DIP type IC is used to remove the ICs. All of the solder on the pins can be melt at same time then it easy to remove the IC. I do not have such kind of soldering iron. |  |

However, there is the soldering iron heated by gas. It is convenient to carry. |

|

Therefore it can't be placed on the desk directly. The stabilized soldering iron stand is necessary. When making the electronic circuit, sometime I forgot the existence of soldering iron, because I have devoted to the parts, wiring etc. It was serious when I noticed, desk was burning. You need to choose the iron stand with appropriate weight which can hold iron stably. Also you need to choose the iron stand that fit the form of iron. Usually I wipe the tip of iron with moistened sponge. Therefore I use the iron stand with the place for sponge. This is your taste.

As for good solder, the containment rate of tin is high. The finish of soldering is beautiful. The price is a little bit high. There are several kinds of solder, solder wire( thread form solder ) is convenient for electronic circuit making. This solder wire is doing the structure of the pipe and flux is included inside. Flux melts together with the solder and the solder becomes easy to attach to the component leads. There are some thickness of solder wire. I am usually using the one that diameter is 0.5 mm. The containment rate of the tin is 60%.

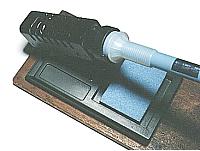

I will introduce the instruments that can be used for desoldering. Solder pump  This is the tool that can be absorbed the melted solder with the repulsion power of the spring that was built in with the principle of the piston. This is the tool that can be absorbed the melted solder with the repulsion power of the spring that was built in with the principle of the piston.The usage is shown below. Pushe down the knob of the upper part of the pump against to spring until it is locked. Melt the solder of the part that wants to absorb solder with iron. Apply the nozzle of the pump to the melted solder part. Push the release knob of pump. Then the plunger of the pump is pushed up with the power of spring and solder is absorbed inside the pump. You need to do this operation quickly, otherwise the part gets damage by the heat. A little practice is needed. Desoldering wire  This is made of thin copper net wire like a screen cable in a coaxial cable. This is made of thin copper net wire like a screen cable in a coaxial cable.Like water inhales to cloth, the solder is absorbed to the net wire by a capillary tube phenomenon. The usage is shown below. Apply the desoldering wire to the part that wants to take solder. Apply the soldering iron from the top and Melt the solder. The melted solder is absorbed to desoldering wire with a capillary tube phenomenon. At this time you absorb solder while shifting desoldering wire. When the solder can not be removed in the once, remove repeatedly while shifting the desoldering wire. There are several kinds of width of desoldering wire. I am using the one with 2mm width. |

|