See SuperGlue, Hot Glue, Epoxy.

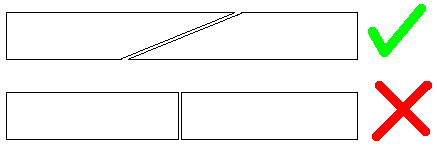

In general, rough or interlocking surfaces adhere best. Sand, knurl, or scratch the surfaces to be glued first. Also, a glue joint spread over a large area will work better than one that has a small surface area, so when attaching two items, cut them at a diagonal, to increase the area over which the glue will hold.

Based on cyanoacrylate, which is an acrylic resin. Ultra fast ;30 second set with a few hours to full cure. Stronger tensile than shear. There are different types, intended for different materials; get the right one for your application. Works best on very hard, non-flexable, smooth materials. Not for glass or soft plastics like ABS. Perfect for Acrylic, Plexiglass, Ceramic, etc..

They key point to using SuperGlue is to use less. The tiniest drop will cover a huge surface and cure faster to a harder bond. Of course, that means the surfaces much match very closely; SuperGlue does not fill well. To get around that, use baking soda as a filler and curing agent.^ The cure is activated by moisture, but too much will weaken the bond. To hold items together, wrap with dental floss (non-waxed) and drip superglue over the fibers.

Other uses: Lock nuts in low vibration applications. Heat to drive off fumes (toxic) which will adhere to fingerprints, making them visable. Small wounds can be held together by superglueing the skin over the cut. Can stop cracks from growing in glass.

Remove with acetone.

A class of thermoplastic adhesives. Generally less toxic. Flexible. There are many different types, which melt at a wide range of temperatures. Some can be further cured via moisture or UV. Excellent for fabrics, soft plastics, and general low strength repairs. It can fill large areas and does not shrink when cooling. In fact, you can build up layers or fill a mold to make an object entirely out of hot glue. Specialized versions can bond just about anything.

Other uses: Applying textures to surfaces. Quickly bonding parts via part of a surface to let the stronger glue on the rest of the surface cure. Make a quick mold to reproduce a shape. Temporary gaskets and seals can be formed with a bead. Waterproof electronics or other small items by encapsulating them. Secure small parts with irregular shapes which are difficult to clamp.

A class of reactive prepolymers and polymers which contain epoxide groups.

A gun for cartridges of epoxy with a mixing tube makes dispensing much easier and less messy, while ensuring a complete mix in exactly the correct proportions.

However, sadly, there is no standard for mixing tubes (nozzels) and cartridge interfaces, so great care must be taken to find matching parts. Even for one mfgr, you can find multiple different interfaces. Buying directly from the cartridge mfgr is the best option, but most expensive. To purchase 3rd party nozzels, first find the cartridge mfgrs part number for the matching nozzel and then search for 3rd party units which advertise compatibility with that part number or cartridge.

Also, great care must be taken to get the correct gun and plunger for the cartridge. For example, there are two types of guns: EPX Plus II and DMA 50/51. They appear to be totally identical, except that the EPX gun has the smaller cylinder on the left as you hold the gun, and the DMA is smaller on the right. This means that the plunger will have the ratchet (which is pushed forward by the handle of the gun) on the opposite side; they can not simply be flipped over. For the 1:1 mix cartridges, where the two cylinders are the same side, this doesn't matter. But for 2:1 (or other) mix systems, the smaller piston must be on the correct size.

On top of this, the distance between the cylinders in the cartridge are not always the same. For the 50 mL cartridges, the standard distance applies, but there are also 37 mL cartridges which require a narrower plungers to match the spacing of the cylinders. For example, 3M DP100 is a 1:1 mix, and typically comes in a standard 50mL cartridge. DP420 is a 2:1 mix, the black comes in a 37mL cartridge. These can work in the same guns, because the gun has an extra slot, but great care must be employed in getting the right plunger. For example, there are 4 possibilities for a 2:1 plunger: 1. 50mL DMA (Standard spacing, small pad on the right), 2. 37mL DMA (Narrow, small right) 3. 50mL EPX (Wide, small left), 4. 37mL EPX (Narrow, small left).

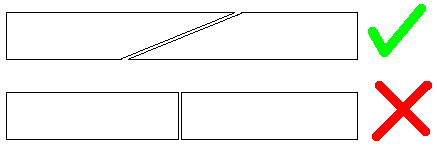

DMA 50 gun: |

EPX Plus II gun: |

See also:

| file: /Techref/adhesives.htm, 7KB, , updated: 2021/1/17 19:21, local time: 2025/10/26 08:07,

216.73.216.180,10-8-63-169:LOG IN

|

| ©2025 These pages are served without commercial sponsorship. (No popup ads, etc...).Bandwidth abuse increases hosting cost forcing sponsorship or shutdown. This server aggressively defends against automated copying for any reason including offline viewing, duplication, etc... Please respect this requirement and DO NOT RIP THIS SITE. Questions? <A HREF="http://techref.massmind.org/techref/adhesives.htm"> Construction Adhesives</A> |

| Did you find what you needed? |

Welcome to massmind.org! |

Welcome to techref.massmind.org! |

.