About the Printed Circuit Board

[Menu]>[Manufacturing of Original PCB]

| Good one is made. |

Many sheet of the same circuits can be made with the same quality. The same one is made whoever assembles. |

|

Cheaply made. (In the case for the industry) |

If fixing (the soldering) in the parts even if it doesn't wire, the electronic circuits can be assembled. It is possible to do the construction at short time and it can do the manufacturing cost cheaply. All constructions can be mechanized, too. |

| Compactly made. | The small wiring can be made using the print technique. |

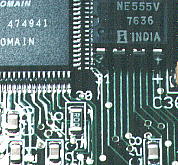

The copper foil is set up to the both sides of the insulation board and there is one which can picture the wiring pattern in the double sided, too.

The copper foil is set up to the both sides of the insulation board and there is one which can picture the wiring pattern in the double sided, too.| The one which has the shield(Earth plate to prevent the electromagnetic influence of the wiring of the double sided), inserting the sheet copper at the center of the insulation board. | |

| The one to make the insulation board the multilayer structure and for the wiring pattern to become solid.(There are ones such as the 50 layers, too) | |

| The one where the insulation board is thin like the film. |

As for the recent parts, the SMT(Surface Mount Type) is used by the dwarfing. This doesn't soldering the lead line of the part in the back of the printed circuit board and solderings the lead line of the part to direct to wire.

As for the recent parts, the SMT(Surface Mount Type) is used by the dwarfing. This doesn't soldering the lead line of the part in the back of the printed circuit board and solderings the lead line of the part to direct to wire.