Case making for Ultra High Accuracy Digital Clock (Ver2)

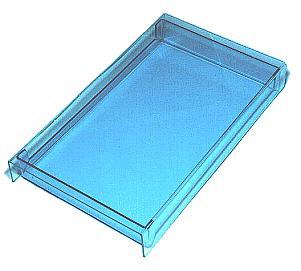

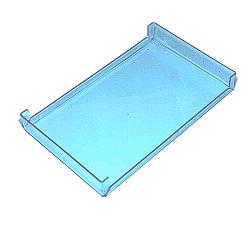

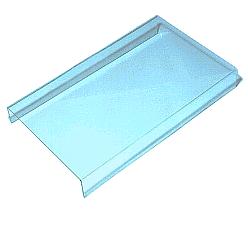

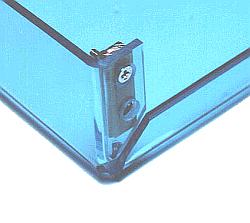

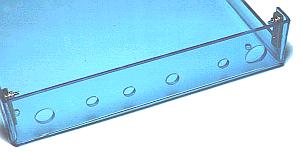

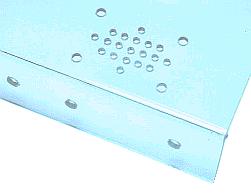

I will introduce the way of making the case which used the acrylic board on this page. I used "Bending apparatus-2" to bend the acrylic board.  I used the acrylic board colored sky blue for back part. The back part is constructed by the back board, the stave and the reinforcement part. The reinforcement part must be bent first.  I used the acrylic board colored glass for cover part. The cover part should be made after making the back part. Because it is necessary to be bent according to the size of the back part. To make length on either side the same, the end of being one should be cut after a bend is ended.   The cover fixation metal fittings to have made with the board of brass are put to the four corners of the back part. The cover fixation metal fittings to have made with the board of brass are put to the four corners of the back part.The board of brass has 6-mm width, 3-mm thickness, about 20-mm length. Two holes of 2.5 mm are opened. One is to fix metal fittings on the back part. Another is used for the fixation of the cover. Metal fittings are fixed on the back part by the plate screw of 2 mm. It shaves a hole with the tip of the 6-mm drill and it makes the head of the plate screw and the board of the acrylic fiber flat. In the hole to fix a cover, it makes the female screw of 3 mm with tap. It makes a 5-mm hole in the acrylic fiber in the back part which corresponds to this screw part and the screw for the cover installation makes be accepted.   The holes for a power connector, a TV antenna connector, a volume, a time setting switch and so on at the right surface of the back part are opened. At first, it makes a 3-mm hole. It makes a hole big gradually with the big drill and in the last, it is made a needed size with the reamer. It makes big little by little while confirming with the part. When too big, it isn't possible to return to the origin. It opens out carefully. Also, the acrylic fiber has broken when applying big power. Careful work is needed.  The holes for the fixation of the back part, the speaker and the ventilation are opened to the cover. The holes for the fixation of the back part, the speaker and the ventilation are opened to the cover.The holes for the ventilation are opened at the top and the bottom. |