Stepper motors are devices, which convert electrical impulses into discrete

mechanical rotational movements. In a typical stepper motor, power is applied

to two coils. Two stator cups formed around each of these coils, with pole

pairs mechanically offset by ½ a pole pitch, become alternately

energized North and South magnetic poles. Between the two stator-coil pairs

the offset is ¼ of a pole pitch.

The permanent magnet rotor has the same number of pole pairs as the stator

coil section. Interaction between the rotor and stator (opposite poles attracting

and like poles repelling) causes the rotor to move ¼ of a pole

pitch per winding polarity change.

Motors are available in either 2 coil (bipolar) or 4 coil (unipolar) windings.

In the unipolar version, the coils are bifilar (two side by side wires) wound

on each stator half and opposite ends of each pair are connected together

to form a center tapped coil. With this method, the flux is reversed by powering

either one end or the other of the bifilar coil pair with the center connected

to common. For a bipolar motor, an external device referred to as an H-Bridge

can be used to reverse the polarity of the winding and thus the flux. An

H-Bridge can also drive a unipolar motor by not connecting the center tap

(common) lead or using only one of the windings in the pair.

Unipolar stepper motors require only 4 transistor switches which greatly

simplifies the drive circuitry when compared to the 8 transistors required

to drive a bipolar motor (dual H-Bridges). However, for unipolar stepper

motors to have the same number of turns per winding as a bipolar motor, smaller

diameter must be employed so that both windings may fit in the space of one.

The resistance increases due to the smaller wire diameter. Due to increased

resistance, unipolar stepper motors have 30% less torque at low step rates.

At higher step rates, the torque outputs are approximately the same.

For a stepper motor to take one step a four part switching sequence is involved

which is commonly referred to as Wave Drive.

Sequence |

Coil A |

Coil B |

1 |

+ |

off |

2 |

off |

+ |

3 |

- |

off |

4 |

off |

- |

In the chart above, + indicates the coil is conducting in the forward direction

with one end being positive with respect to ground. The - indicates that

the coil is conducting in the opposite direction. Continuing the sequence

as outlined above causes the rotor to rotate in a forward direction. Reversing

this sequence causes the motor to rotate in the reverse direction. The coils

only are required to be energized long enough for the rotor to move to its'

next position. If the coil remains energized, it will lock the shaft of the

motor and this situation is commonly used for stopping or putting on the

brakes. The torque developed in this manner is referred to as the motor's

holding torque. Operated at a fixed frequency, the electrical input to the

motor appears as a two-phase 90-degree shifted square wave.

The no load or constant load accuracy of a 7.5 degree/step motor is within

0.5% noncumulative. This means that the positioning error is always the same

whether the rotational movement is one step or 1000 steps. Since the step

error is noncumulative, it averages itself out to zero within a 4-step sequence,

which corresponds to 360 electrical degrees. The 4-step sequence uses the

same coil, magnetic polarity and flux path. With this in mind, the most accurate

method of positioning would be obtained by stepping in multiples of 4.

It is also possible to step the motor according to an 8-part sequence to

obtain half steps. For example a motor with a step size of 7.5 degrees/step

could be half stepped to obtain motion of 3.75 degrees/step. Applications

utilizing this method will suffer a lower holding torque on every other half

step since only one winding will be energized. Accuracy will also suffer,

as winding and flux conditions are not similar for each ½ step.

The half step sequence is listed in the chart below.

Sequence |

Coil A |

Coil B |

1 |

+ |

+ |

2 |

+ |

off |

3 |

+ |

- |

4 |

off |

- |

5 |

- |

- |

6 |

- |

off |

7 |

- |

+ |

8 |

off |

+ |

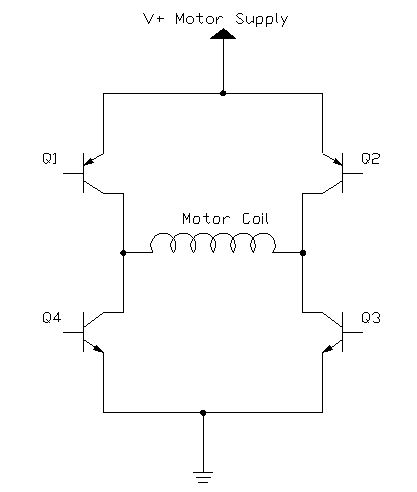

The drawing below depicts a simple H-Bridge. It consists of two pairs of

transistors connected to each end of the motor coil. Q1 and Q2 are connected

to the positive motor supply source. Q3 and Q4 are connected to ground. By

putting a positive voltage on the base of one of the transistors, it will

cause the transistor collector/emitter junction to conduct.

By switching transistors Q1 and Q3 on, it will cause current to flow through

the motor coil in the forward or + direction. By switching Q2 and Q4 on,

it causes current to flow through the motor coil in the reverse or - direction.

The logic controlling which transistors are switched must be quite precise

as switching transistors Q1 and Q4 or Q2 and Q3 on at the same time will

result in shorting the power supply directly to ground which will destroy

the transistor pair and possibly the power supply as well.

Logic must be provided to inhibit any programming error, which would result

in switching the wrong transistors on at the incorrect time. Additionally,

timing circuitry should be employed that the correct transistors are switched

on only after the others are switched off. Simply driving the H-Bridge directly

from a microcontroller would be ill advised. On power-up, the outputs of

many microcontrollers go high momentarily which would instantly destroy an

H-Bridge without the proper inhibit circuitry for disallowed conditions.

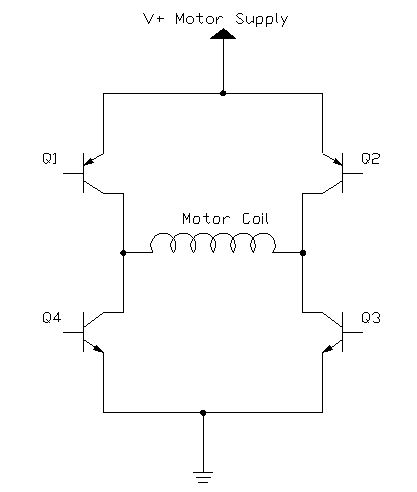

Whenever an inductor is energized, higher than normal current is drawn while

the magnetic field of the coil builds. Conversely, when the inductor is

de-energized, the magnetic field in the coil collapses causing a voltage

to be induced in the inductor and current to flow in the opposite direction.

The reverse current flow may damage the switching transistors in the circuit.

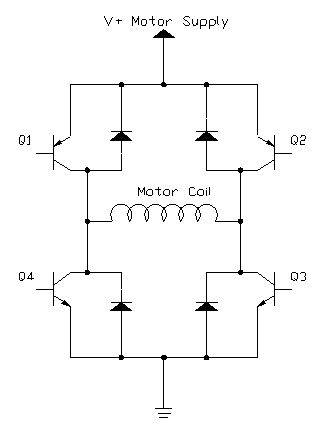

In order to correct the problem with the polarity reversal caused by the falling magnetic field inducing a current in the inductor, snubber diodes are installed. The direction of the diodes is such that during normal operation, the diodes do not conduct. When the falling magnetic field causes reverse current flow, the diodes conduct this current directly to ground and away from the switching transistors. The circuit below depicts a simple H-Bridge with snubber diodes installed.

The Allegro UDN2998 Dual Full Bridge Motor Driver IC handles all of the problems of H-Bridges and incorporates this technology in a single package. Current prices for this chip are less than $7 in single quantities. The UDN2998 features:

3 Amp peak output current

2 Amp continuous current

Output voltage to 50 Volts

Integral output suppression diodes

Output current sensing

TTL / CMOS compatible Inputs

Internal thermal shutdown circuitry

Crossover -Current protection

12 Pin package

Due to the logic circuitry preventing crossover-current protection (switching

on the wrong transistors creating a short circuit) each side of the dual

bridge has an enable and phase input instead of controlling the switching

transistors directly. A truth table is depicted below.

Enable Input |

Phase Input |

Output 1 |

Output 2 |

Low |

High |

High |

Low |

Low |

Low |

Low |

High |

High |

High |

Open |

Low |

High |

Low |

Low |

Open |

Referring back to the Wave Drive table for half stepping our motor and also the UDN2998 truth table, we can make up a logic table depicting the output for our microcontroller. This table is shown below.

Microcontroller Output Table

Sequenced for Half-Stepping

Sequence |

Coil A |

Coil B |

Coil B Enable RA3 |

Coil B Phase RA2 |

Coil A Enable RA1 |

Coil A Phase RA0 |

1 |

High |

High |

0 |

0 |

0 |

1 |

2 |

High |

Off |

1 |

0 |

0 |

1 |

3 |

High |

Low |

0 |

1 |

0 |

1 |

4 |

Off |

Low |

0 |

1 |

1 |

0 |

5 |

Low |

Low |

0 |

1 |

0 |

0 |

6 |

Low |

Off |

1 |

0 |

0 |

0 |

7 |

Low |

High |

0 |

0 |

0 |

0 |

8 |

Off |

High |

0 |

0 |

1 |

0 |

If you compare the half step and full step tables, you will notice that all of the full step sequences appear somewhere in the half step table, but not in the same order. This information is useful in building a look-up table in your program and not having to duplicate the lines of code that would appear in both half step and full step output sequences.

Pin |

Function |

1 |

Ground |

2 |

Phase A |

3 |

Enable A |

4 |

Output 1A |

5 |

Bridge A Supply Common |

6 |

Output 2A |

7 |

Output 2B |

8 |

Bridge B Supply Common |

9 |

Output 1B |

10 |

V+ Motor Supply |

11 |

Enable B |

12 |

Phase B |

You can obtain a complete data sheet at www.allegro.com that provides more

information about temperature, heat sinking and other modes of operation

such as the chopper mode.

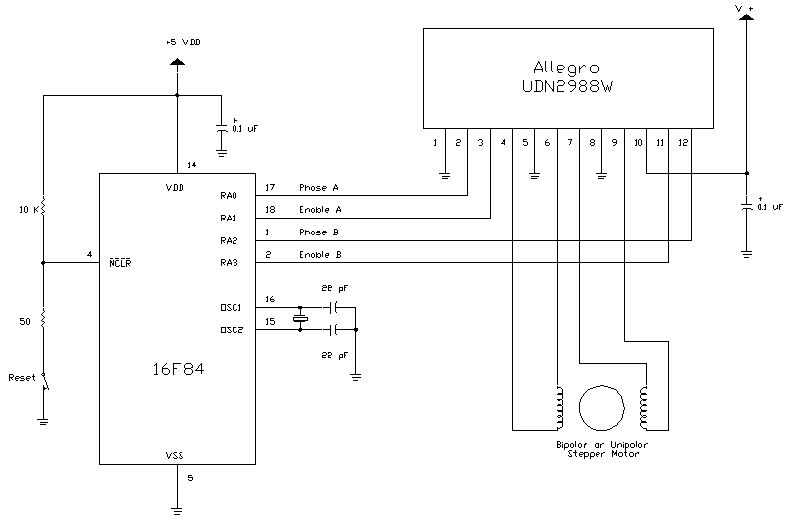

The following schematic diagram shows a circuit, which places what we have

discussed into practice. I am using a 16F84 microcontroller in this example,

however, any microcontroller which is supported by JAL will work. You will

only need to make a few changes in both the circuit and the program to

accommodate the changes.

Power for the circuit comes from one or two external power supplies. Operating

off a single supply is a bit trickier due to the noise generated by the switching

transistors. The 5 volt supply for the microcontroller should be well regulated.

It is very important not to omit the two 0.1 uF capacitors shown and they

should be placed as close as possible to their respective chips. These are

decoupling capacitors and if omitted can cause unreliable operation or the

circuit not to function at all. I experienced lack of function without these

capacitors when operating from the same power supply and even including a

5 volt regulator for the microcontroller.

Power for the motor should be based on the current and torque requirements

for the motor and what kind of load the motor must move. A little experimentation

may be in order to find just the right value for the motor supply voltage.

Increasing the voltage will increase the motor current and the torque produced

while at the same time increasing the heat produced by the UDN2998.

You will notice both a 10 K and a 50 Ohm resistor connected to the reset

lead of the microcontroller. You might be able to omit the 50 Ohm resistor.

The 10 K resistor pulls the reset lead up to the 5 volt supply, without it,

the microcontroller will remain in the reset mode and the circuit will not

operate. The 50 ohm resistor is included as recommended by Microchip Technologies

in order to prevent the reset pin from going negative when the reset switch

is pressed.

The UDN2998 is not the only H-Bridge that is manufactured by Allegro or by

other manufacturers. You might select a different chip based on your project

requirements. Pins 5 and 8 of the UDN2998 are the ground returns for each

side of the H-Bridge. If necessary, you could install current limiting or

current sensing resistors at this point. Beware of the wattage rating of

any resistors installed here as a motor drawing several Amps at even 12 Volts

will require a resistor of considerable wattage to prevent it from burning

up.

Following is the JAL library that you will need to include in your program

to drive a stepper motor using this configuration.

--

-- Program: bipolib.jal library

--

-- Date: 14 July 2000

--

-- Author: G. Shearer

-- Vanderbilt University

-- Nashville, TN

--

-- Purpose: for driving both bipolar and unipolar stepper motors

-- uses Allegro UDN2998 dual H bridge

-- Copyright (C) 2000 G. Shearer

--

-- This library is free software; you can redistribute it and/or

-- modify it under the terms of the GNU Library General Public

-- License as published by the Free Software Foundation; either

-- version 2 of the License, or (at your option) any later version.

--

-- This library is distributed in the hope that it will be useful,

-- but WITHOUT ANY WARRANTY; without even the implied warranty of

-- MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the GNU

-- Library General Public License for more details.

--

-- You should have received a copy of the GNU Library General Public

-- License along with this library; if not, write to the

-- Free Software Foundation, Inc., 59 Temple Place - Suite 330,

-- Boston, MA 02111-1307, USA.

--

procedure stepout ( byte in seq, byte in speed ) is

-- sends seq nibble to output

if seq == 0 then

port_a = 0b_0001

elsif seq == 1 then

port_a = 0b_1001

elsif seq == 2 then

port_a = 0b_0101

elsif seq == 3 then

port_a = 0b_0110

elsif seq == 4 then

port_a = 0b_0100

elsif seq == 5 then

port_a = 0b_1000

elsif seq == 6 then

port_a = 0b_0000

elsif seq == 7 then

port_a = 0b_0010

else

port_a = 0b_1010

end if

delay_1ms( speed )

end procedure

procedure fullforward ( byte in speed ) is

-- makes one full step in the forward direction

stepout( 1, speed )

stepout( 7, speed )

stepout( 5, speed )

stepout( 3, speed )

end procedure

procedure fullreverse ( byte in speed ) is

-- makes one full step in the reverse direction

stepout( 3, speed )

stepout( 5, speed )

stepout( 7, speed )

stepout( 1, speed )

end procedure

procedure halfstep ( bit in direction, byte in out seq, byte in speed ) is

-- makes one half step in the proper direction and remembers which half

step

for 4 loop

if direction == true & seq < 7 then

seq = seq + 1

elsif direction == true & seq == 7 then

seq = 0

elsif direction == false & seq > 0 then

seq = seq - 1

elsif direction == false & seq == 0 then

seq = 7

end if

stepout ( seq, speed )

end loop

end procedure

procedure fullstep ( bit in direction, byte in speed ) is

-- detects forward/reverse direction and calls proper fullstep procedure

if direction == true then fullforward ( speed )

else fullreverse ( speed )

end if

end procedure

I have included a copy of the library file

so you will not need to type the whole thing in yourself. This library contains

a few procedures, but from a program point of view, you will only need to

add the line:

include bipolib

in your program. Every time you wish to have the motor take a full step,

include the following line in your program:

fullstep ( direction, speed )

where direction is either true for forward or false for reverse and speed

is the number of milliseconds between steps.

For half-stepping, you will need to initialize the step sequence at the beginning

of your program. Just add the following line:

var byte seq = 0

which will start half stepping on the first half step. The procedures in

the library will then keep track of which half step to take each time it

is called. Each time you wish to take a half step, use the following line

in your program:

halfstep ( direction, seq, speed )

where direction and speed are exactly the same as for full stepping and seq

is the sequence counter used to keep track of which half step to take.

Here is s quick rundown on each of the procedures contained in bipolib.jal

Procedure fullstep

Determines forward / reverse

Calls either fullforward or fullreverse

Passes speed variable

Procedure halfstep

Determines last sequence

Determines forward / reverse

Increments sequence

Calls stepout

Passes sequence and speed variables

Procedure fullforward

Sets sequence

Calls stepout

Passes sequence and speed variables

Procedure fullreverse

Sets sequence

Calls stepout

Passes sequence and speed variables

Procedure stepout

Looks up binary output based on sequence value

Sets port a

Adds delay based on speed

Following is a demonstration program that utilizes bipolib.jal and exercises

the stepper motor to prove functionality of the circuit and

library.

--

-- Program: biptest.jal

--

-- Date: 13 July 2000

--

-- Author: G. Shearer

-- Vanderbilt University

-- Nashville, TN

--

-- Purpose: Demo program for bipolib.jal

-- ( bipolar stepper motor library)

--

-- Copyright (C) 2000 G. Shearer

--

-- This library is free software; you can redistribute it and/or

-- modify it under the terms of the GNU Library General Public

-- License as published by the Free Software Foundation; either

-- version 2 of the License, or (at your option) any later version.

--

-- This library is distributed in the hope that it will be useful,

-- but WITHOUT ANY WARRANTY; without even the implied warranty of

-- MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the GNU

-- Library General Public License for more details.

--

-- You should have received a copy of the GNU Library General Public

-- License along with this library; if not, write to the

-- Free Software Foundation, Inc., 59 Temple Place - Suite 330,

-- Boston, MA 02111-1307, USA.

--

-- includes

include 16f84_4

include jlib

include bipolib

-- configure ports

port_a_direction = all_output

-- initialize variables

var byte speed = 3

var bit direction = true

var byte seq = 0

-- here da program

forever loop

direction = true

for 100 loop

fullstep ( direction, speed )

end loop

direction = false

for 100 loop

fullstep ( direction, speed )

end loop

direction = true

for 200 loop

halfstep ( direction, seq, speed )

end loop

direction = false

for 200 loop

halfstep ( direction, seq, speed )

end loop

end loop

I believe the demonstration is self-explanatory. I encourage you

to experiment with the demonstration program to get a feel of how it

operates.

I am certain that some typos or omissions have crept into this explanation

so I would be grateful for any corrections to errors you have observed. Please

write to me at g.shearer@vanderbilt.edu

I welcome your comments and would be pleased to learn of any projects you

have done which utilize the information, circuits, library or demonstration

program contained here.

See also:

Questions:

saeedturkSPAM at TakeThisOuTyahoo.com well it was knowledgefull but i don know what is "jal". do someone has c/C++ code and an 74xxx based circuit for bi-directional ctrl form pc port?. I will weight. saeedturk@yahoo.com+

Well, JAL is Just Another Language. Look at Steppers for general information.

Code:

Comments:

| file: /Techref/piclist/jal/DrivingBipolarStepperMotors.htm, 40KB, , updated: 2020/6/3 09:55, local time: 2025/10/6 23:22,

216.73.216.214,10-2-72-254:LOG IN

|

| ©2025 These pages are served without commercial sponsorship. (No popup ads, etc...).Bandwidth abuse increases hosting cost forcing sponsorship or shutdown. This server aggressively defends against automated copying for any reason including offline viewing, duplication, etc... Please respect this requirement and DO NOT RIP THIS SITE. Questions? <A HREF="http://techref.massmind.org/Techref/piclist/jal/DrivingBipolarStepperMotors.htm"> Driving Bipolar Stepper Motors</A> |

| Did you find what you needed? |

Welcome to massmind.org! |

|

The Backwoods Guide to Computer Lingo |

.