Is it:

A. "Manufacturing jobs strangled by government regulation.."

B. “Outsourcing of work to other countries where worker pay is

lower...”

C. “Them damn ‘illegals’ a’come all up in a’here,

a’steal’n my jerb!”

WRONG: None of the above.

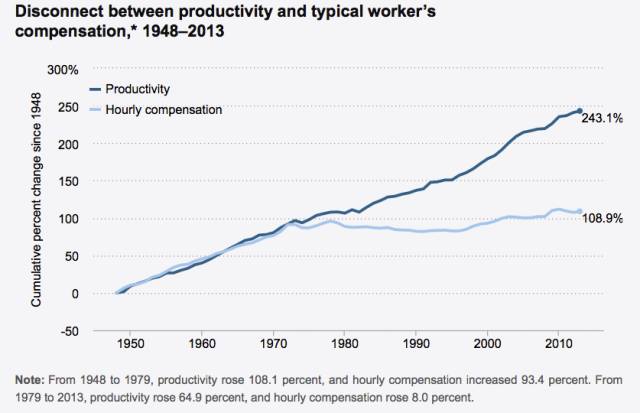

They were automated away. Workers were replaced with machines because technology advanced, the corporations invested in it and reaped the rewards. Worker productivity continues to increase, while worker pay is stagnant because automation increases productivity and reduces worker demand. The job gains we have seen are all in the minimum wage jobs (not worth automating) and high end jobs (too difficult to automate). The jobs in the middle are worth automating and can be automated. The obvious solution is to shift people up into jobs that require more education. The blockage is overpriced education and lazy people more interested assessing blame than in learning. The real solution may be new age hippie Makers: Dropping out, becoming self sufficient, and/or embracing automation and letting the robots they build and own do the work for them.

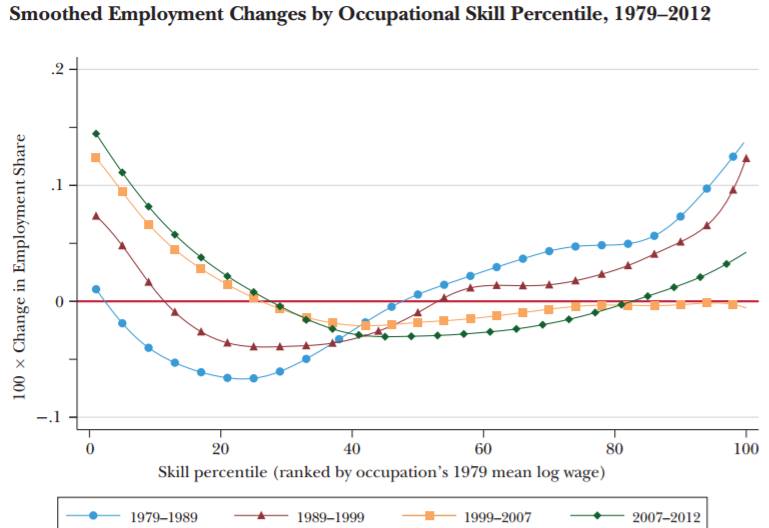

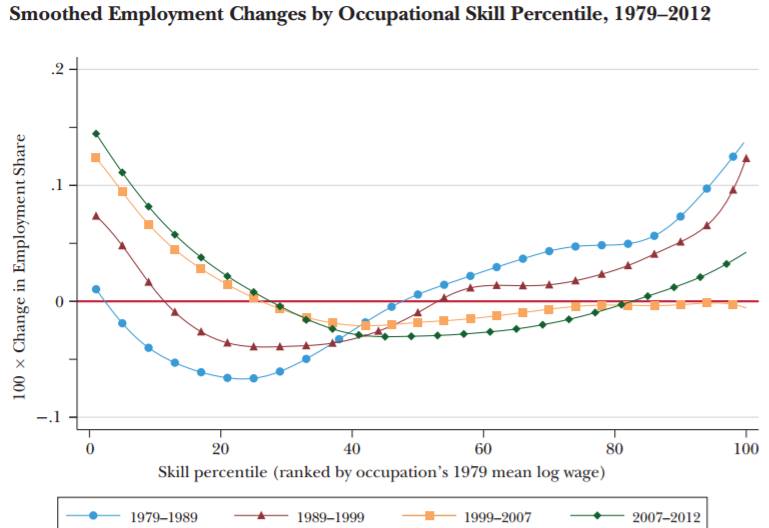

If you look at a graph with the income a specific job provides arranged from left to right, with minimum wage on the far left, and CEO’s on the right, and setup the vertical axis to show jobs lost or gained, what you will find is that while we have actually gained jobs over all, those gains have all been on the far left (minimum wage jobs, not worth automating) and on the right (jobs the require creativity, education, deep understanding, etc... which can not yet be automated). In the center, jobs where humans do hard, repetitive, mechanical work that does not require great education, are actually being lost.

It started “computers” in the early 60’s. At that time “computer” was a job description, the “computers” were humans whose job it was to compute. You’ve probably heard of the Unibomber; Ted Kaczynski, but did you know why he was so pissed off? Two things: 1. He was literally abused in Henry Murray’s human experiments at Harvard, and 2. His life's calling was doing computing tasks in mathematics where were replaced by the first machine computers. The Unibombers manifesto is very worth reading, although his methods were ineffective. We will see more and more like him as jobs are lost, and cruelty continues.

But the real impact was felt with factory jobs in the late 60s and 70s. We built huge machines that turn out parts, process foods, and produce simple goods far faster, cheaper, and in most cases, with higher quality (or at least higher consistency) than humans. It was at this point that we see the increase in productivity decouple from the increase in wages. Human workers continued to earn the same amount, while producing more with the help of machines and automation purchased by the owners and investors of the companies.

http://s3.epi.org/files/pdf/why-americas-workers-need-faster-wage-growth.pdf

Then in the 70’s and 80’s big ticket, complex, high volume items like cars, planes, appliances were transitioned into robotic factories. At that time, we started seeing some of the production which had been outsourced in the 60’s, especially heavy items such as cars, return to the USA, because increasing shipping costs will always limit outsourcing.

But that return did NOT mean a return to employment of factory workers, because the new factories were automated it takes far fewer humans to tend, program, and repair robots than it takes to do that work directly. The new jobs were either minimum wage (robot tenders) or high end (programmers, repair, management); no skilled craftsman need apply.

In the 90’s the automation trend continued and expanded to include construction, road work, transportation systems, laboratory work, and many other areas. In the 2000’s we are seeing a transition to the automation of custom work. CNC, 3D printing, open CAD, etc... took a bite out of custom fabrication and prototyping shops while at the same time reducing the cost of prototyping and customized production. Again, more production returned to the USA, this time because of wage stabilization in China, India, etc... where workers are now earning only a fraction of what US workers cost, instead of a small fraction.

All in all, because of the production which has returned to the USA, it turns

out that since the 70’s only 13% of jobs were lost to outsourcing, 85%

were lost to automation:

http://conexus.cberdata.org/files/MfgReality.pdf

Today, middle class jobs are going away at the fastest rate ever.

http://economics.mit.edu/files/11563

https://futureoflife.org/wp-content/uploads/2017/01/Andrew-McAfee.pdf

Robots are becoming less expensive, easier to setup and program, and so are

replacing more and more small scale jobs on a wider bases. Baxter, and Sawyer

from ReThink Robotics are good examples.

http://www.rethinkrobotics.com/

For under $22,000 one of these robots can be acquired by a medium or even

small business and put to work with a simple set of guided movement and button

presses. The operator literally grabs the robots are and moves it to the

first location, presses a button, moves the arm to the next location, and

so on. A simple menu can be used to select actions like “center over

this object” given a picture for reference, or “offset each placement

by this grid arrangement” to fill up the empty spaces in a box. More

complex operations are easily built up from basic trained motions; for example,

“put X objects into the box, then close the lid and move the box down

the line and get an empty”. Job setups are saved and can be recalled

instantly anytime a job needs to be re-run. Think about how much even a minimum

wage worker costs a business owner. Then realize that you only have to buy

Baxter once...

Budweiser just delivered the first big rig full of beer via a totally autonomous 18 wheeler. It drove with a human on board, but he literally crawled in the back and went to sleep as it rolled down the road. Truck drivers make $50 to 75 thousand. They can only drive 8 hours a day, by law so that $150,000 truck is sitting there doing nothing for the trucking company 2/3rds of the time. A self driving truck needs only a minimum wage “truck tender” to watch over it, load and unload, report breakdowns and do simple repairs and maintenance. So the trucking industry, with a one time investment of a few thousand per truck, can reduce labor costs by $35 to $60 thousand per year, trippel their operational capacity, and probably decrease loss by increasing safety (self driving cars are stunningly safe compared to humans). My rough calculations are a savings of $20 to $60 BILLION a year for the industry as a whole.

In the end, since the 1970’s 85% of jobs lost were due to automation:

http://conexus.cberdata.org/files/MfgReality.pdf

So... what is the answer for the humans who are being made redundant?

And by technology, I mean everything from 3D printers to Mulch; Robots to Rainwater Catchment; CNC machines to Chainsaws. One of my favorite youtube channels is called "Primitive Technology" where an unknown man silently demonstrates things like how to build a home from sticks and mud, make pottery, baskets, forge metal, etc...

Food: Of course, I don’t suggest we leave modern innovations behind. A 1/5 acer lot in Pasadena, home of the Dervaes family produces roughly 5,000 pounds of food a year and uses solar panels to run the computers by which they take orders from local restaurants for edible flowers for fancy salads. FarmBot.io offers a CNC machine like gardening robot said to produce enough veggies for one person and pay for itself in 3 to 5 years use. Closer to home, Ag Pals provides excellent design and installation of rainwater harvesting and aquaponic systems for food production using 1/10th the water and 6 to 10 times the density. OurSunCooks.com makes cheap but very effective solar cookers from commonly available materials.

Shelter: I’ve had the privilege of working with two different groups who built 3D printers large enough to print houses. Andrey, at TotalKustom.com has printed (small) castles and (large) hotel suites. The guys at VestaPrinter.comwill sell you a 3D concrete (tiny) house printer. It won’t print a mansion, but a structure large enough to live in is very possible, and you can add on as many rooms as you wish, just feed cement, water, rebar, etc... These homes are perfectly legal and meet construction standards because the 3D printed parts are simply the forms into which rebar is placed and cement poured. Although this has not yet been done, it would combine perfectly with strawbale construction. The Tiny Home movement has been featured at past Maker Faires via CityDesignInc.com

Parts: In addition to food and shelter, massive libraries of replacement parts are available online for 3D printing at sites like Thingiverse.com

Products: And you can’t be replaced by a machine if you are the one using the machines to make products that other people will purchase. Multiple small businesses and startups were enabled by their founders learning to solder, program, cast plastics, and other critical skills at the local Maker Faires. Many of these people have gone on to make a living selling products. AryaBall is a local success story.

The Maker Movement: And so we come to the Maker Movement: Maker Faires, the STEAM Maker Fest, Maker Places, and all form of interesting open source projects. These are a way for people to share, largely outside the capitalize monetary system, their abilities, successes, failures, and lessons on how to make things yourself.

The typical Maker Faire has more than 200 exhibitors who are not selling or buying anything; they are not charged for the exhibit space. These people are proud of what they made, and the Faire gives them a chance to be appreciated for it. But more than that, they are universally willing to share how they did it, and show others how they can as well. The cost of hosting the Faire is paid by sponsors, mostly corporations eager to advertise their products, and by the ticket price for the attendees. Every Faire includes “Hands On Activities” where attendees learn how to make something themselves. Nearly always included is Soldering where a simple electronic circuit is constructed and a valuable skill is learned.

The range of methods and results is truly stunning. At the Faire, you will see everything from Aquaponics to Automatons, Basket weaving to Bio hacking, Candle making to Computer driven cars... There is a misconception that Maker Faires are about high tech, and while there is a lot of that, we fully support ANY making of any kind. If you can teach people to sew, we want you. Canning, Gardening, Husbandry, Weaving, Pottery, Haberdashery, you name it, if you make it, we will make room for you.

What do you make?

See also:

| file: /Techref/member/JMN-EFP-786/making_is_the_solution_to_job_loss_from_automation.htm, 17KB, , updated: 2019/6/24 09:47, local time: 2025/10/16 21:15,

owner: JMN-EFP-786,

216.73.216.53,10-2-207-162:LOG IN

|

| ©2025 These pages are served without commercial sponsorship. (No popup ads, etc...).Bandwidth abuse increases hosting cost forcing sponsorship or shutdown. This server aggressively defends against automated copying for any reason including offline viewing, duplication, etc... Please respect this requirement and DO NOT RIP THIS SITE. Questions? <A HREF="http://techref.massmind.org/Techref/member/JMN-EFP-786/making_is_the_solution_to_job_loss_from_automation.htm"> Making is the Solution to Job Loss from Automation.</A> |

| Did you find what you needed? |