Also: Gallery, Board Layouts

Since the Linistepper is an open source project, users can easily modify

the code or hardware to support thier needs. A few have taken the time to

share thier favorite mods:

The Linistepper Equatorial Drive: Roman and

ceefna^ made

an Equatorial Stepper Drive for taking long

exposure pictures of the stars.

Hazimin

Fauzi^ has

translated the Linistepper asm code into

SDCC^

C with some variations:

-

Automatic low power mode after timeout instead of manual high/low power input.

-

Coil current tables are all in EEPROM

-

No support for run time mode changes

There are two versions:

Max Ries: two modes (3600 and 400 step/rev) w/

on the fly switching and available IO.

The LiniClock project: Roman created a

very nice clock with hand moved by a stepper motor. The code to keep track

of time fit nicely into the Linisteppers PIC along side the stepper drive

code.

OCNC says:

I made a mechanical modification to the Linistepper {ed: version 1, this

sort of mount is more or less the default for version 2} by installing

3-position female headers (digikey S7036-ND) where the TIP 122's go. I then

took the heatsink from a Masscool CPU Cooling Fan

(tigerdirect item #S457-1111) and drilled and tapped four holes into

it at 1/2" centers and 9/16" up from the edge. I also drilled and tapped

two holes on the fin surface of the heatsink (lies coplanar with the circuit

board). These holes line up with the two outer TIP holes and are 19/32" from

the heatsink edge (same edge that the TIP holes are referenced from). They

also are drilled and tapped to a depth to penetrate two fins. The stand off's

were cut from 1/4" aluminum tubing to a finish length of 9/16". The screws

used are all #4-40.

The ones holding the TIP's down are 3/8" long and the two for the stand off's

are 1" long. Following the best mechanical practise I used a lock washer

and flat washer under the head of each screw. Belleville washers are recommended

for the TIP's but they seem too expensive at $.50 each so I used split ring.

I rubbed the backs of the TIP's on a sharp file to get the best contact surface

possible. I also filed the mating heatsink surface and then polished it with

some steel wool. In place of mica and paste I used Berquist silicone heat

pads (digikey BER220-ND). With 1A steppers at 24V I'm unable to detect by

touch any heat rise in the TIP's.

I feel that this is a better solution than the bracket that the kit suggests

because it eliminates a heat transfer junction and it allows for very easy

replacement of the TIP's. Also if you have to drill and prepare a piece

of angle for a bracket why not just do the same right on a fan cooled heatsink?

The small cost of the additional parts seems insignificant compared to the

utility of the final product.

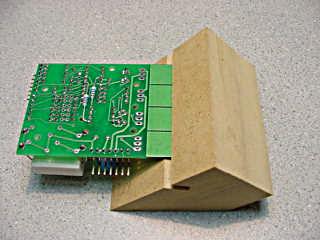

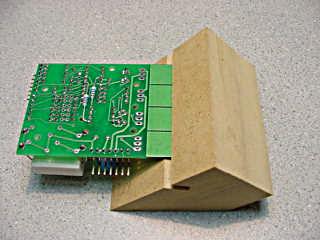

J.R. Hatcher says:

I included a few pictures, one is my invention to hold the board while soldering,

it's fast because it's just laying in the groove very loose, yet it holds

it flat and off the table.

{Ed: Some people like to make thier own linistepper PCBs. The Linistepper

is an open source project and we enjoy seeing people take advantage of that

when they are able. The people listed here were also kind enough to share

thier board files and we've agreed to host them here. If you aren't big on

makeing your own PCBs, do keep in mind that we sell the

PCB for less than you can pay a board house

to make them and the kit of all parts (including

the pre-programmed PIC) is less than what you can buy the parts for from

any supplier.

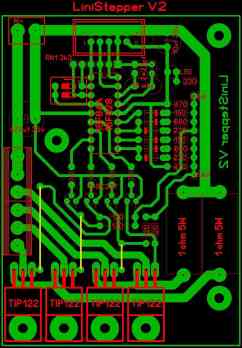

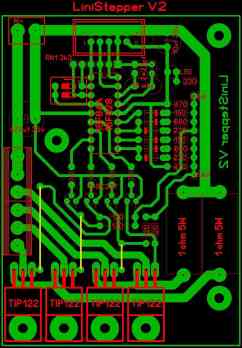

Siniarsa Dewanata posted this very nice layout for the Linstepper version

2.

LiniStepper-SiniarsaDewanata.zip

Murat Sakman posted an alternate layout for the Linistepper Version 2 on

the Linistepper facebook group:

LiniStepper-MuratSakman.zip

The only concern we have with that layout is that the transistors should

be spread apart so they have more surface area on the heatsink to dissipate

all the heat. And perhaps they should be standing up, rather than laying

down, to allow direct connection to the heatsink. Other than that, this is

a very nice single sided layout, with only a few jumpers. Nice work!

Iwan Tejasukmana says: "Apparently the layout by Murat Shakman changed the

step and direction pin. I retraced the layout with schematic and found this

alteration."

Patricio Oholeguy says:

i just made an interesting improvement to posix version of the Linistepper

by aligning the transistors and a few things more.

Linistepper

with aligned transistors.zip

Posix says:

Well folks I have completed my drivers,

the knee-mill and I can tell you that linistepper and dremel can dig into

a piece of pine like hot knife through butter! I just did some engraving

on the back piece of a pcb and it works nice. I even made a mistake of inputting

-2mm rather than -0.2mm and it just dug into the pcb and started writing.

So I can conclusively say that linistepper with 1.2A step-syn motors works

like a charm! I'm using a 12v ATX PSU and an additional $5 12v computer case

fan is blowing across the linistepper to provide some fresh air to those

alu coolers.

Well folks I have completed my drivers,

the knee-mill and I can tell you that linistepper and dremel can dig into

a piece of pine like hot knife through butter! I just did some engraving

on the back piece of a pcb and it works nice. I even made a mistake of inputting

-2mm rather than -0.2mm and it just dug into the pcb and started writing.

So I can conclusively say that linistepper with 1.2A step-syn motors works

like a charm! I'm using a 12v ATX PSU and an additional $5 12v computer case

fan is blowing across the linistepper to provide some fresh air to those

alu coolers.

I can tell you that at 200 steps you get your standard driver with all the

buzzing and vibrations of any other full step driver. 400 improves somewhat

and brings a smile to a newbie.

1200 is where the action begins and a big grin materialises on anyones face

who is used to steppers buzzing and jumping and vibrating. If anyone say

the gecko video of mariss drawing that spiral will immediately know what

I'm talking about.

The linistepper really is good value for money, whether you build it or buy

it from piclist.com. The reason I didn't buy mine from james are twofold,

first they would've gotten "lost in the post" and second educational value.

For someone who burns their fingers on a soldering iron regularly then, by

all means, purchase a finished quality item from james at piclist.

Linistepper-review.brd

Linistepper-review.sch

Here are Posix's boards hard at work. Notice that the heatsinks are missing!

Posix promises to add them when he starts doing prolonged runs. His steppers

are small and he is using an underpowered supply so the power drivers are

not being stressed to much, but they WILL over heat if he isn't carefull.

That CNC machine is Posix's own design and very nicely made.}

Questions:

file: /Techref/io/stepper/linistep/mods.htm, 12KB, , updated: 2017/7/19 13:17, local time: 2025/10/17 23:53,

216.73.216.53,10-2-207-162:LOG IN

|

| | ©2025 These pages are served without commercial sponsorship. (No popup ads, etc...).Bandwidth abuse increases hosting cost forcing sponsorship or shutdown. This server aggressively defends against automated copying for any reason including offline viewing, duplication, etc... Please respect this requirement and DO NOT RIP THIS SITE. Questions?

<A HREF="http://techref.massmind.org/Techref/io/stepper/linistep/mods.htm"> Linistepper, Open Source Stepper Controller Modifications, Stepper motor, </A> |

| Did you find what you needed?

|

| |

Welcome to techref.massmind.org!

|

.

Well folks I have completed my drivers,

the knee-mill and I can tell you that linistepper and dremel can dig into

a piece of pine like hot knife through butter! I just did some engraving

on the back piece of a pcb and it works nice. I even made a mistake of inputting

-2mm rather than -0.2mm and it just dug into the pcb and started writing.

So I can conclusively say that linistepper with 1.2A step-syn motors works

like a charm! I'm using a 12v ATX PSU and an additional $5 12v computer case

fan is blowing across the linistepper to provide some fresh air to those

alu coolers.

Well folks I have completed my drivers,

the knee-mill and I can tell you that linistepper and dremel can dig into

a piece of pine like hot knife through butter! I just did some engraving

on the back piece of a pcb and it works nice. I even made a mistake of inputting

-2mm rather than -0.2mm and it just dug into the pcb and started writing.

So I can conclusively say that linistepper with 1.2A step-syn motors works

like a charm! I'm using a 12v ATX PSU and an additional $5 12v computer case

fan is blowing across the linistepper to provide some fresh air to those

alu coolers.